Inconel® 600 – UNS N06600 – W. Nr. 2.4816 – Nickel Alloy 600 – NiCr Alloy

Topics Covered

Introduction of Inconel Alloy 600

INCONEL (nickel-chromium-iron) alloy 600 (UNS N06600/W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability. The limiting chemical composition of INCONEL alloy 600 is shown in Table 1. The high nickel content gives the alloy resistance to corrosion by many organic and inorganic compounds and also makes it virtually immune to chloride-ion stress-corrosion cracking. Chromium confers resistance to sulfur compounds and also provides resistance to oxidizing conditions at high temperatures or in corrosive solutions. The alloy is not precipitation hardenable; it is hardened and strengthened only by cold work.

Chemical Composition

| Content % | Ni | Cr | Fe | Mn | Cu | C | Si | S |

| Min. | 72 | 14 | 6 | – | – | – | – | – |

| Max. | – | 17 | 10 | 1 | 0.5 | 0.15 | 0.5 | 0.015 |

Physical Properties

| Properties | Metric | Imperial |

| Density | 8.47 g/cm³ | 0.306 lb/in³ |

| Melting Range | 1354-1413 ℃ | 2470-2575 ℉ |

Mechanical Properties of Inconel Alloy 600 Rods and Bars

| Condition and Diameter or Distance Between Parallel Surfaces, in. (mm) | Tensile Strength, min, psi (MPa) | Yield Strength (0.2% offset), min, psi (MPa) | Elongation in 2 in. or 50mm or 4D, min, % |

| Cold-worked (as worked): | |||

| Rounds: | |||

| Under 1/2 (12.7) | 120 000 (825) | 90 000 (620) | 7 |

| 1/2 to 1 (12.7 to 25.4), incl | 110 000 (760) | 85 000 (585) | 10 |

| Over 1 to 2 1/2 (25.4 to 63.5), incl | 105 000 (725) | 80 000 (550) | 12 |

| Squares, Hexagons, Rectangles: | |||

| 1/4 (6.35) and under | 100 000 (690) | 80 000 (550) | 5 |

| Over 1/4 to 1/2 (6.35 to 12.7), excl | 95 000 (655) | 70 000 (480) | 7 |

| Hot worked (as worked): | |||

| Rounds: | |||

| 1/4 to 1/2 (6.35 to 12.7), incl | 95 000 (655) | 45 000 (310) | 20 |

| Over 1/2 to 3 (12.7 to 76.2), incl | 90 000 (620) | 40 000 (275) | 25 |

| Over 3 (76.2) | 85 000 (585) | 35 000 (240) | 30 |

| Squares, Hexagons, Rectangles: | |||

| All sizes | 85 000 (585) | 35 000 (240) | 20 |

| Cold-worked (annealed) or hot-worked (annealed): | |||

| Rods and bars, all sizes | 80 000 (550) | 35 000 (240) | 30 |

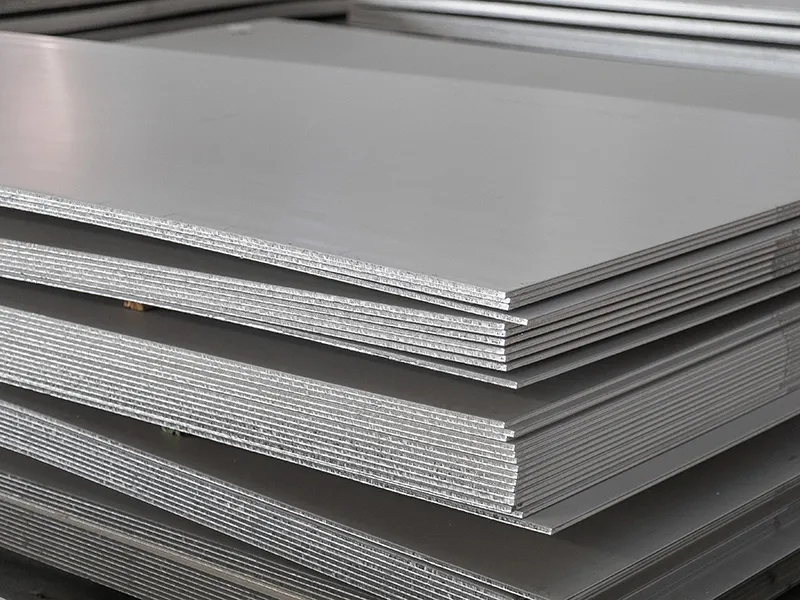

Available Forms and Standards

*Note that the specifications listed are common for this alloy but are for reference only and may be specific to a certain form. The specifications listed are not comprehensive nor indicative of any edition, revision, or similar such as an amendment. Please, reach out to our sales department to request the Material Test Report (MTR) or to confirm your required specifications.

| Forms | Standards |

| Rods & Bars | ASTM B166, ASTM B564 |

| Sheet, Plate, or Strip | ASTM B168 |

| Pipe – Seamless | ASTM B167 |

| Pipe – Welded | ASTM B517 |

| Tube – Seamless | ASTM B163, ASTM B167 |

| Tube – Welded | ASTM B516, ASTM B751 |

| Fitting | ASTM B366 |

| Forging | ASTM B564 |

| Welding Wire | Inconel® FM 82/ UNS N06082/ AWS A5.14 ERNiCr-3/ ASME IX F-No. 43 |

| Stud Bolt / Hex Bolt / Hex Nut / Heavy Hex Nut / Flat Washer |