- UNS N06625

- ASTM B443 Gr. 1, ASTM B446 Gr. 1

- ASME SB 443 Gr. 1, ASME SB 446 Gr. 1

- AMS 5599, AMS 5666, AMS 5837

- Werkstoff 2.4856

- EN 2.4856

- NC22DNb

- NACE MR0175-3

Topics Covered

Introduction of Inconel Alloy 625

INCONEL nickel-chromium alloy 625 (UNS N06625/W.Nr. 2.4856) is used for its high strength, excellent fabricability (including joining), and outstanding corrosion resistance. Service temperatures range from cryogenic to 1800°F (982°C). Strength of INCONEL alloy 625 is derived from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix; thus precipitationhardening treatments are not required. This combination of elements also is responsible for superior resistance to a wide range of corrosive environments of unusual severity as well as to high-temperature effects such as oxidation and carburization.

The properties of INCONEL alloy 625 that make it an excellent choice for sea-water applications are freedom from local attack (pitting and crevice corrosion), high corrosion-fatigue strength, high tensile strength, and resistance to chloride-ion stress-corrosion cracking. It is used as wire rope for mooring cables, propeller blades for motor patrol gunboats, submarine auxiliary propulsion motors, submarine quickdisconnect fittings, exhaust ducts for Navy utility boats, sheathing for undersea communication cables, submarine transducer controls, and steam-line bellows. Potential applications are springs, seals, bellows for submerged controls, electrical cable connectors, fasteners,

flexure devices, and oceanographic instrument components.

Chemical Composition

| Content % | Ni | Cr | Fe | Mn | Mo | Ti | Co | C | Al | Nb+Ta | Si | S | P |

| Min. | 58 | 20 | – | – | 8 | – | – | – | – | 3.15 | – | – | – |

| Max. | – | 23 | 5 | 0.5 | 10 | 0.4 | 1 | 0.15 | 0.4 | 4.15 | 0.5 | 0.015 | 0.015 |

Physical Properties

| Properties | Metric | Imperial |

| Density | 8.44 g/cm³ | 0.305 lb/in³ |

| Melting Range | 1290-1350 ℃ | 2350-2460 ℉ |

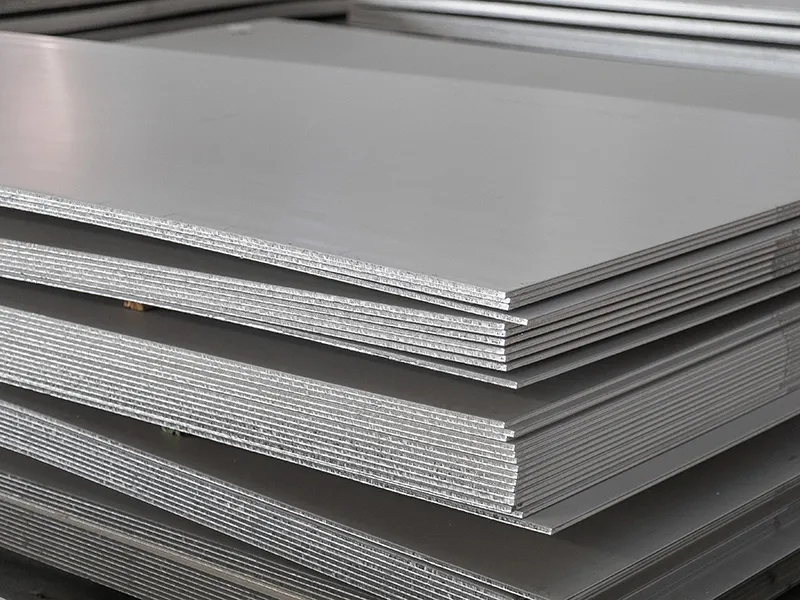

Available Forms and Standards

*Note that the specifications listed are common for this alloy but are for reference only and may be specific to a certain form. The specifications listed are not comprehensive nor indicative of any edition, revision, or similar such as an amendment. Please, reach out to our sales department to request the Material Test Report (MTR) or to confirm your required specifications.

| Forms | Standards |

| Rods & Bars | ASTM B446, AMS 5666 |

| Sheet, Plate, or Strip | ASTM B443, AMS 5599 |

| Pipe – Seamless | ASTM B444, ASTM B829 |

| Pipe – Welded | ASTM B705, ASTM B775 |

| Tube – Seamless | AMS 5581 Type 1, ASTM B444, ASTM B829, |

| Tube – Welded | AMS 5581 Type 2, ASTM B704, ASTM B751 |

| Fitting | ASTM B366 |

| Forging | AMS 5666, ASTM B564 |

| Welding Wire | Inconel® FM 625/ UNS N06625/ W. Nr. 2.4831/ AWS A5.14 ERNiCrMo-3/ ASME IX F-No. 43/ AMS 5837 |

| Stud Bolt / Hex Bolt / Hex Nut / Heavy Hex Nut / Flat Washer | ASTM F468, ASTM F467, |